|

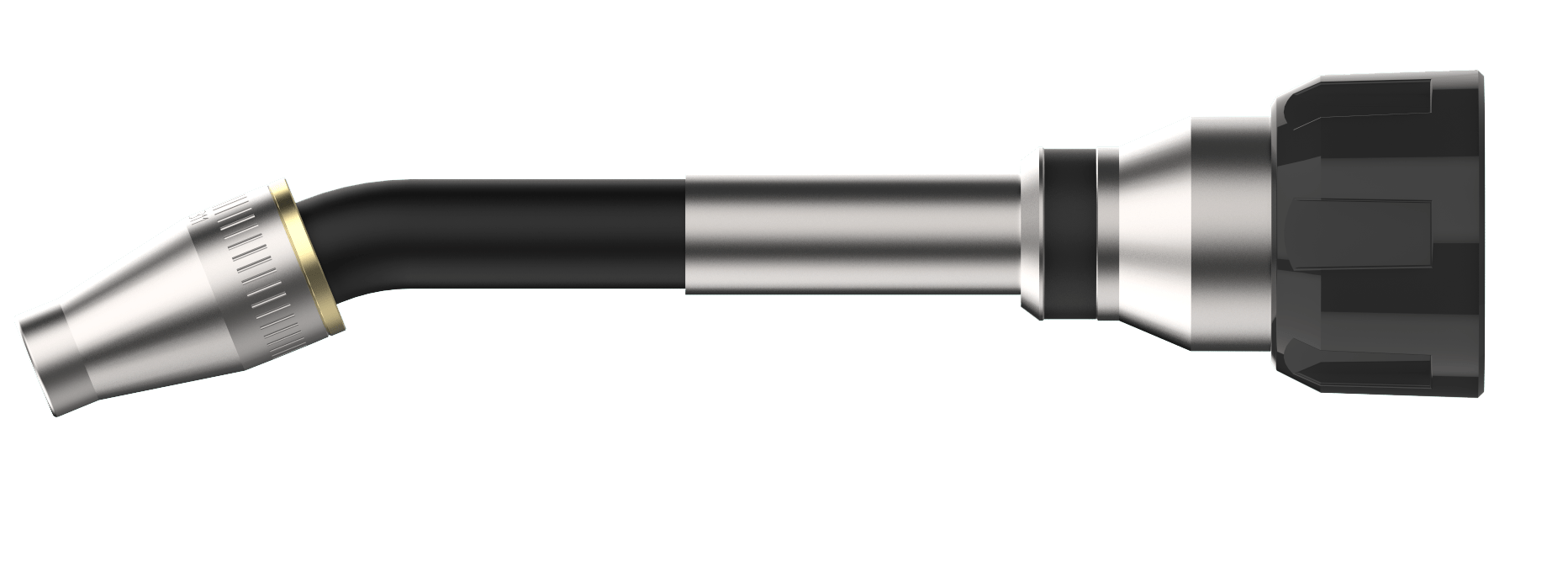

0º |

|

|

Cod: R16.0000 |

|

|

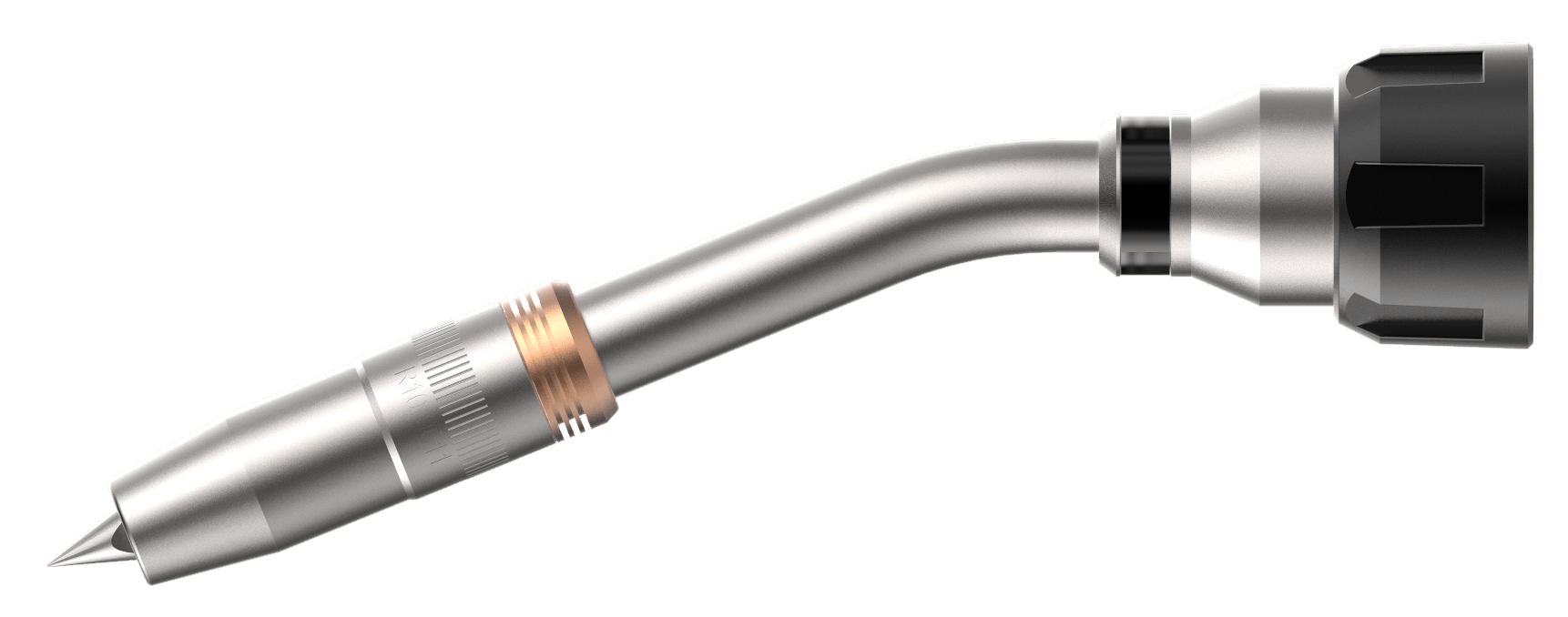

22º |

|

|

Cod: R16.0220 |

|

|

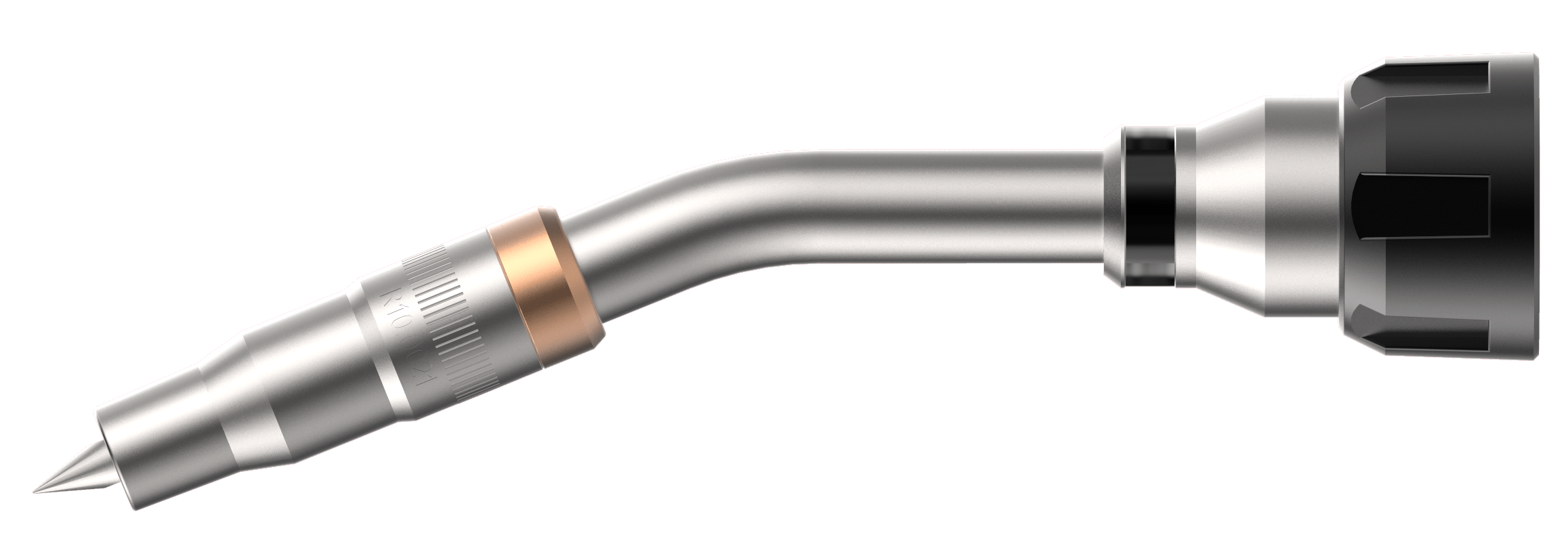

22ºL |

|

|

Cod: R16.0221 |

|

|

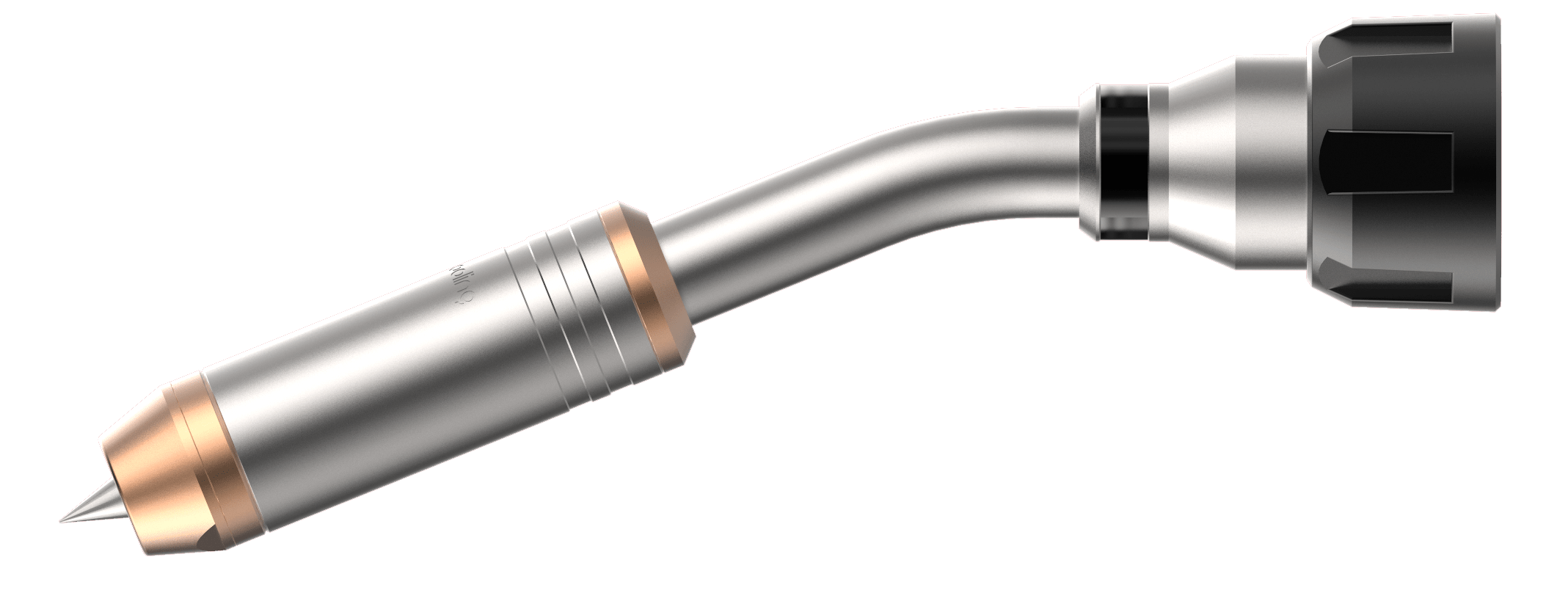

22ºXXL |

|

|

Cod: R16.0224 |

|

|

36ºXXL |

|

|

Cod: R16.0364 |

|

|

45ºXXL |

|

|

Cod: R16.0454 |

|

BOT-60W

Welding process:

MIG/MAG, GMAW, 131, 135.

Liquid cooling.

600 A with CO2 – cycle 100%.

500 A Mix M21 (ISO 14175) – cycle 100%.

Wire 1.0-2.4 mm.

Gas flow 10-20 l/min.

Technical data according to IEC 60974-7

High power MIG / MAG neck model, for applications where the work cycles are long and high power, recharge, beams, very high work intensity and adaptable to a multitude of robotic and automatic applications, the most powerful model with contribution of a single thread.

The welding systems for industrial robots BOTseries are designed for work cycles of 24 hours, developed for an intensive use, precise and specifically adapted to long work cycles.

Advantage of BOTseries collars.

- Compatible with all robot systems iBOT *, eBOT *, cBOT *. This allows you to exchange necks bet ween different systems.

- Stainless steel outer casing, more stability with temperature changes and maintain its TC P continuously.

- Nozzle fully cooled to the tip and with open circuit system.

- Double cooling system with two independent circuits, doubling its cooling capacity.

- Fully independent gas protection system, greater flow in the gas outlet and less porosity.

- Extra cooling at the contact point with the COOLTIP system.

- Possibility of multiple neck geometries for all types of applications.

* iBOT system for robots with hollow wrist shaft and internal wiring to axis 6.

* eBOT system for standard robots with closed wrist and external wiring to axis 6.

* cBO T system for robots that can be used in both standard robots and hollow shaft robots (with the replacement of the adaptation plate).