|

0º |

|

|

Cod: R14.0000 |

|

|

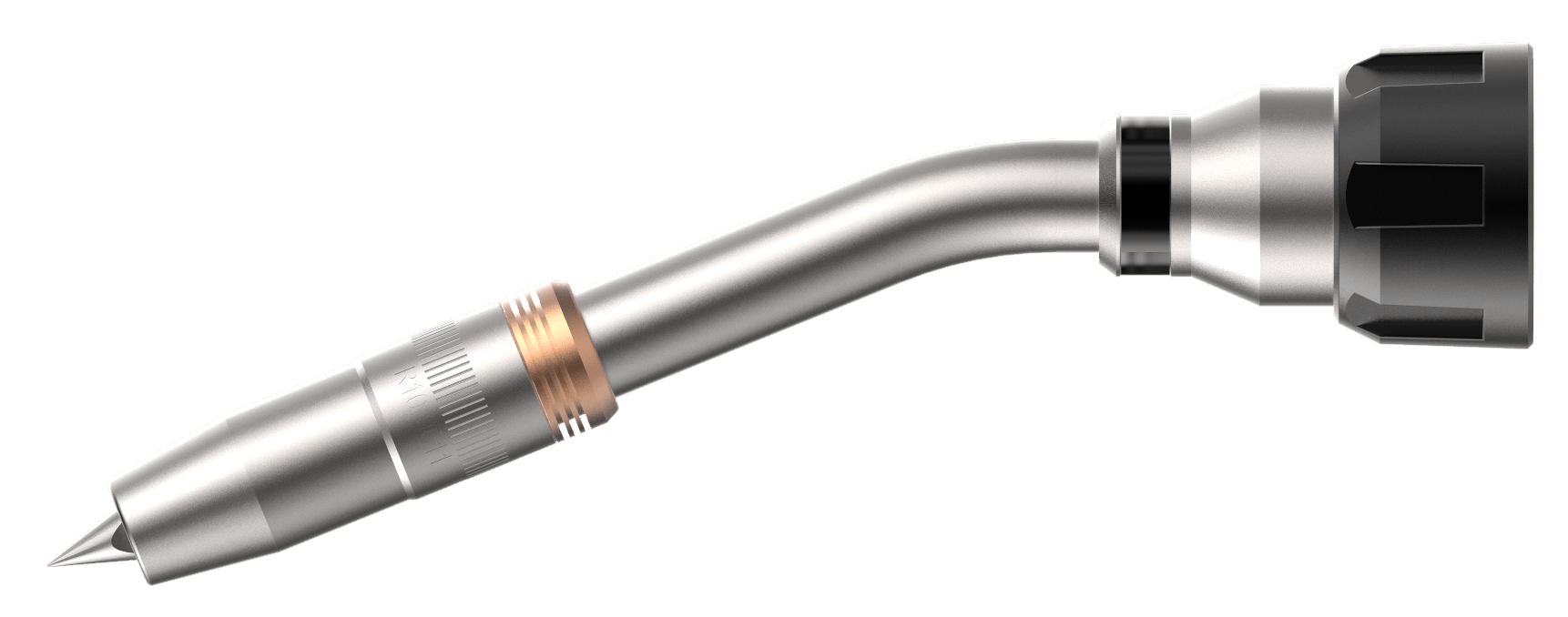

22º |

|

|

Cod: R14.0220 |

|

|

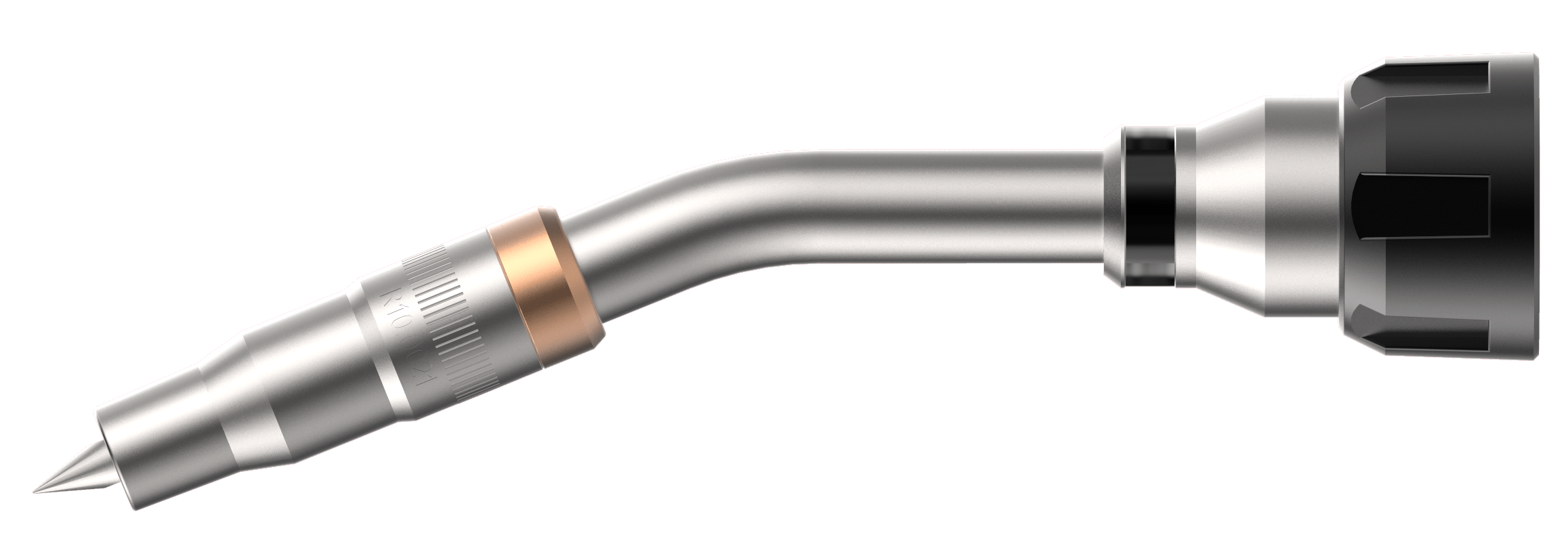

22ºF |

|

|

Cod: R14.0222 |

|

|

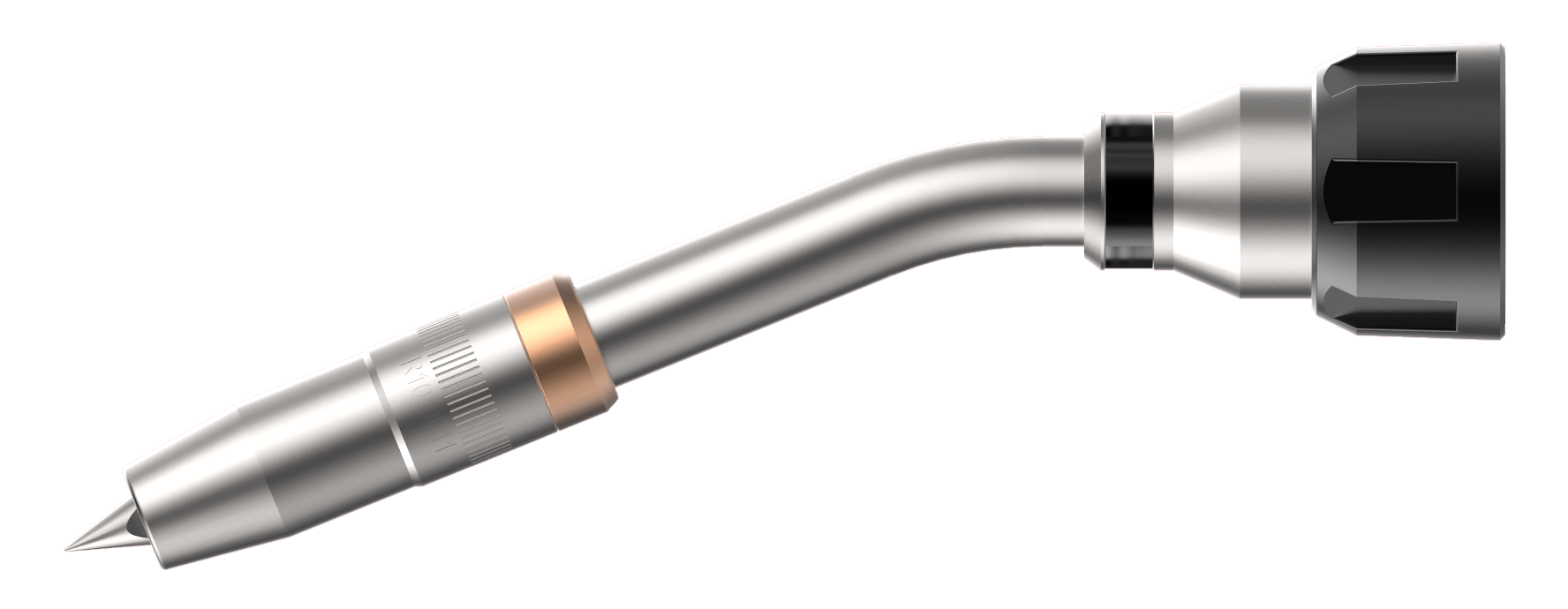

22ºL |

|

|

Cod: R14.0221 |

|

|

22ºFL |

|

|

Cod: R14.0223 |

|

|

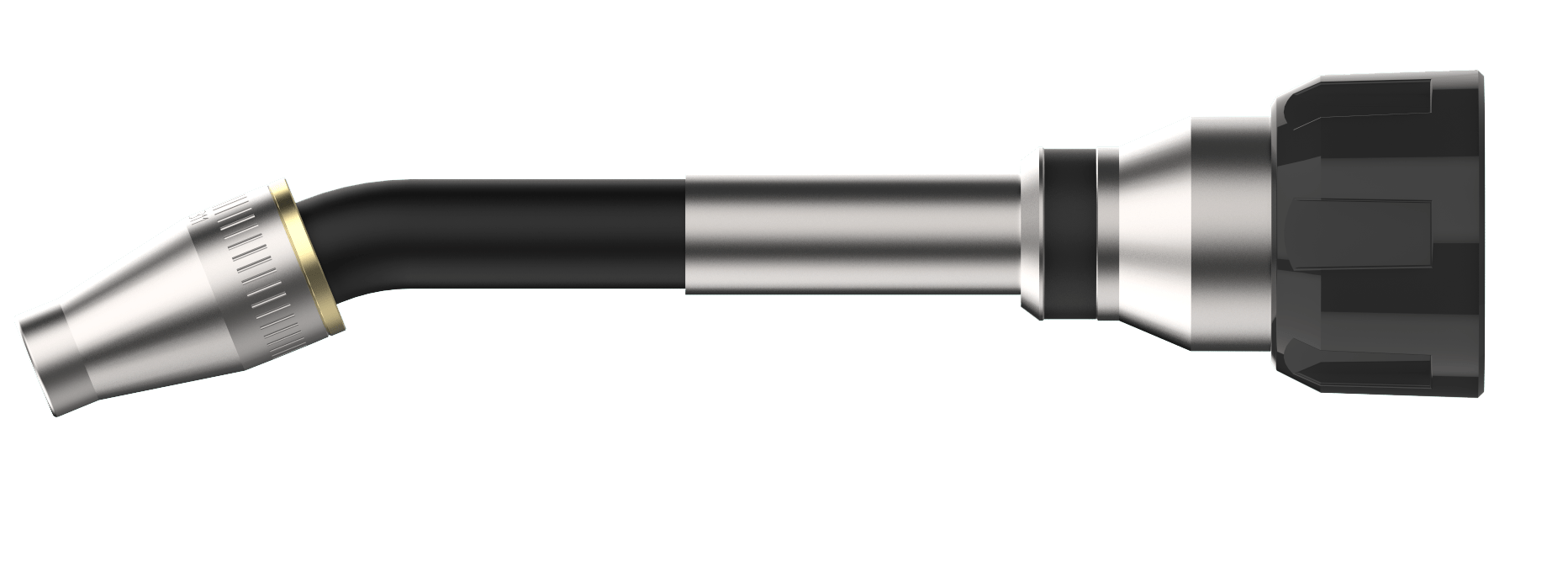

36º |

|

|

Cod: R14.0360 |

|

|

45º |

|

|

Cod: R14.0450 |

|

BOT-40W

Welding process:

MIG/MAG, GMAW, 131, 135.

Liquid cooling.

500 A with CO2 – cycle 100%.

400 A with Mix M21 (ISO 14175) – cycle 100%.

Wire diameter 0.8-1.6 mm.

Recommended gas flow 10-18 l/min.

Technical data according to IEC 60974-7

MIG / MAG neck model with high versatility, very versatile for medium-high work intensity and adaptable to a multitude of robotic and automatic applications, one of the most versatile models.

The welding systems for industrial robots BOTseries are designed for work cycles of 24 hours , developed for an intensive use, precise and specifically adapted to long work cycles

Advantage of BOTseries collars.

- Compatible with all robot systems iBOT *, eBOT *, cBOT *. This allows you to exchange necks between different systems.

- Stainless steel outer casing, more stability with temperature changes and maintain its TCP continuously.

- Double cooling system with two independent circuits, doubling its cooling capacity.

- Fully independent gas protection system, greater flow in the gas outlet and less porosity.

- Extra cooling at the contact point with the COOLTIP system.

- Possibility of multiple neck geometries for all types of applications.

* iBOT system for robots with hollow wrist shaft and internal wiring to axis 6.

* eBOT system for standard robots with closed wrist and external wiring to axis 6.

* cBOT system for robots that can be used in both standard robots and hollow shaft robots (with the replacement of the adaptation plate).