|

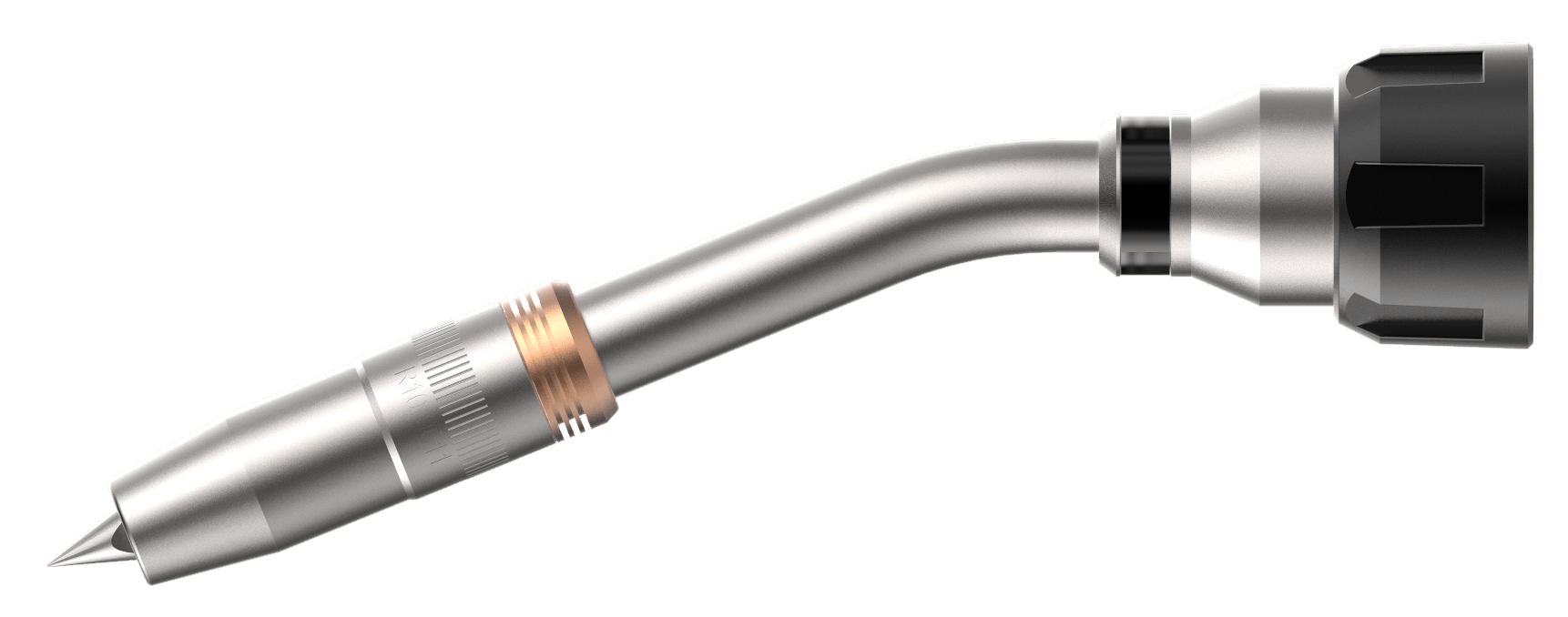

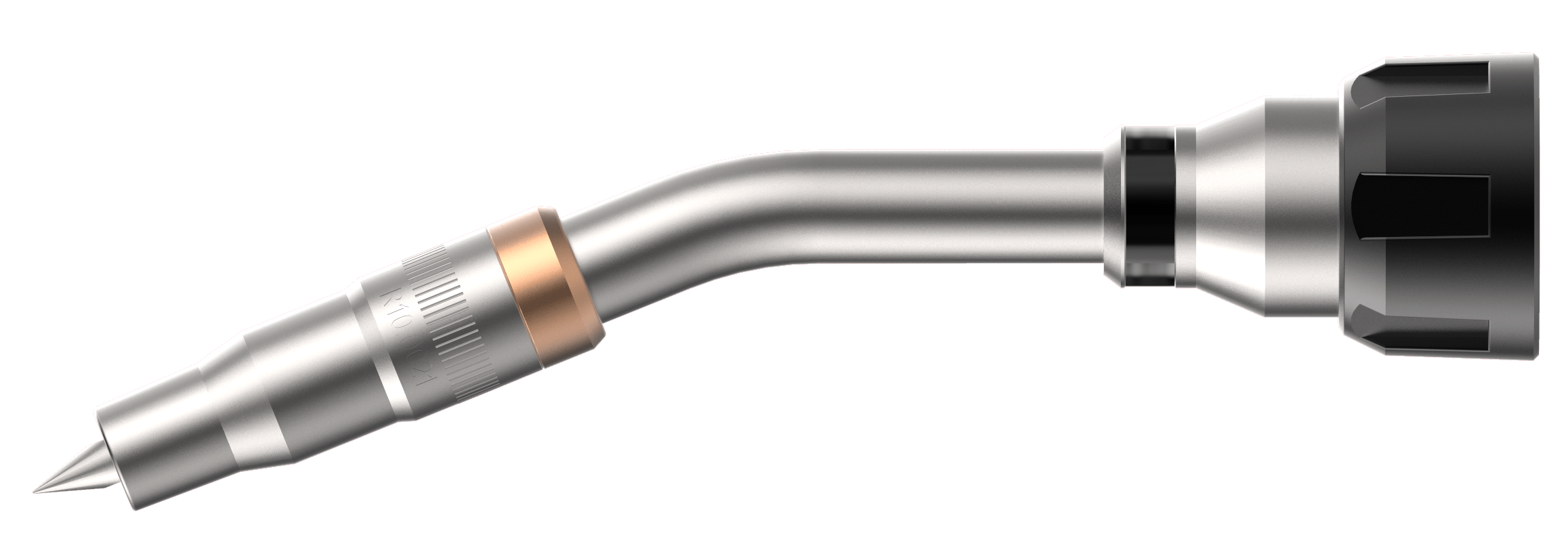

10º |

|

|

Cod: R15.5400 |

|

|

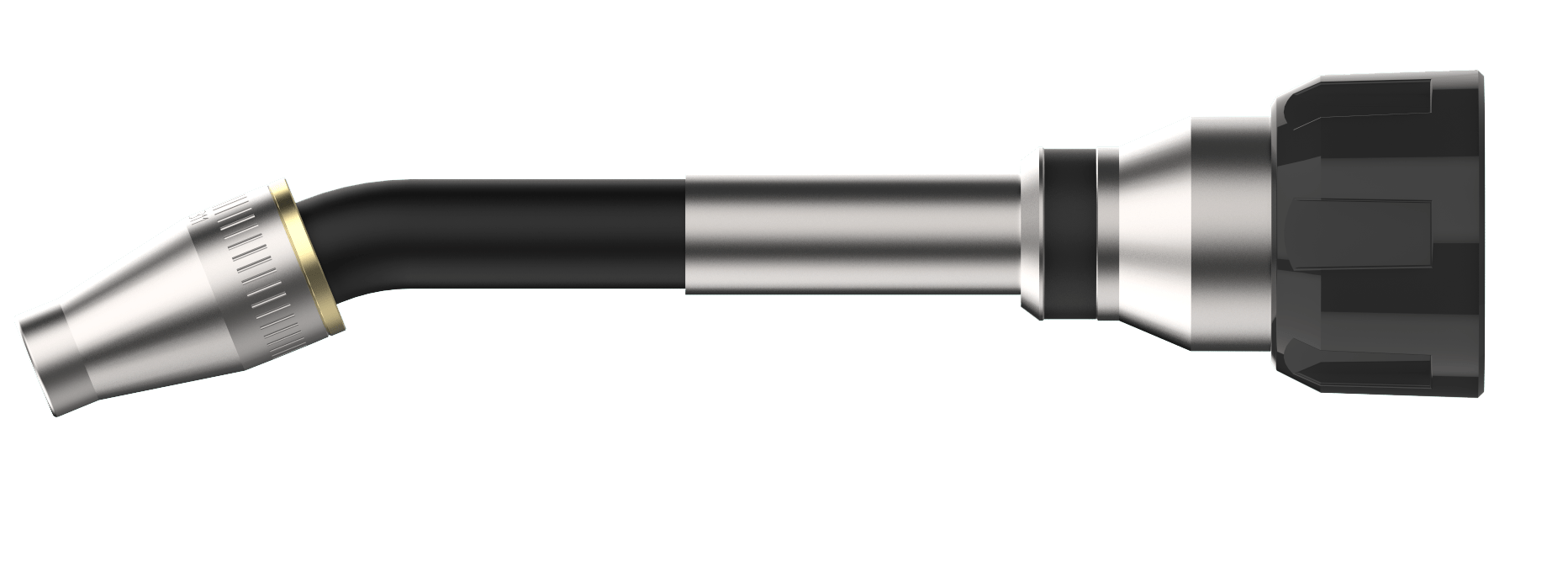

10º |

WCW |

|

Cod: R15.5401 |

|

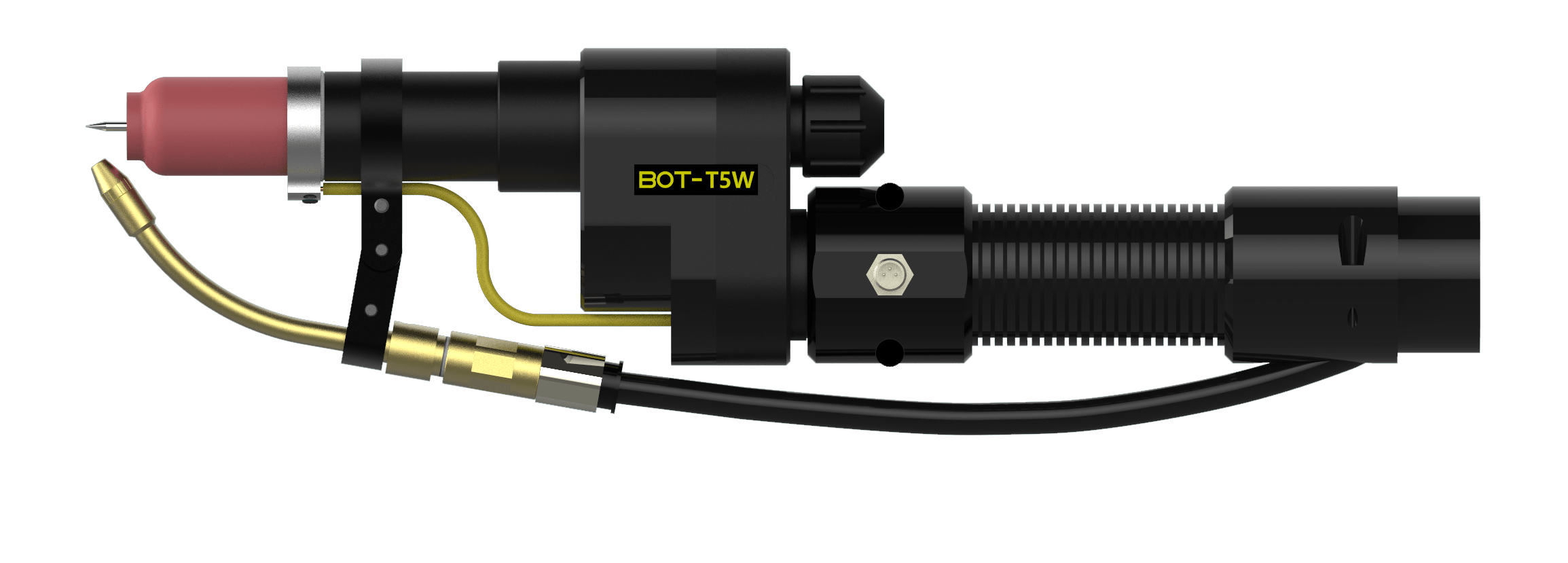

BOT-T5W

Welding process:

TIG, GTAW, 141

Liquid cooling.

400 A CD – cycle 100%.

300 A CA – cycle 100%

Electrode diameter 1.6-4.8 mm

Recommended gas flow 4-12 l/min.

Technical data according to IEC 60974-7

TIG neck model designed for robotic systems, high power capacity for multiple applications with and without supp ly wire, its special spare part guarantees better TCP precision with the electrode change.

The welding systems for industrial robots BOTseries are designed for work cycles of 24 hours, developed for an intensive use, precise and specifically adapted to long work cycles.

Advantage of BOTseries collars.

- Compatible with all robot systems iBOT *, eBOT *, cBOT *. This allows you to exchange necks between different systems.

- Repairable neck head in case of collision or wear.

- High electrode life due to its cooling technology.

- Over sized insulation for HF.

- Ability to use cold wire without changing the neck with the adaptation module.

- Easy regulation of the position of the thread.

* iBOT system for robots with hollow wrist shaft and internal wiring to axis 6.

* eBOT system for standard robots with closed wrist and external wiring to axis 6.

* cBOT system for robots that can be used in both standard robots and hollow shaft robots (with the replace ment of the adaptation plate).

IMPORTANT NOTE: It must be mounted with the anti-collision system itBOT, designed for systems with high frequency.