What is your welding torch power?

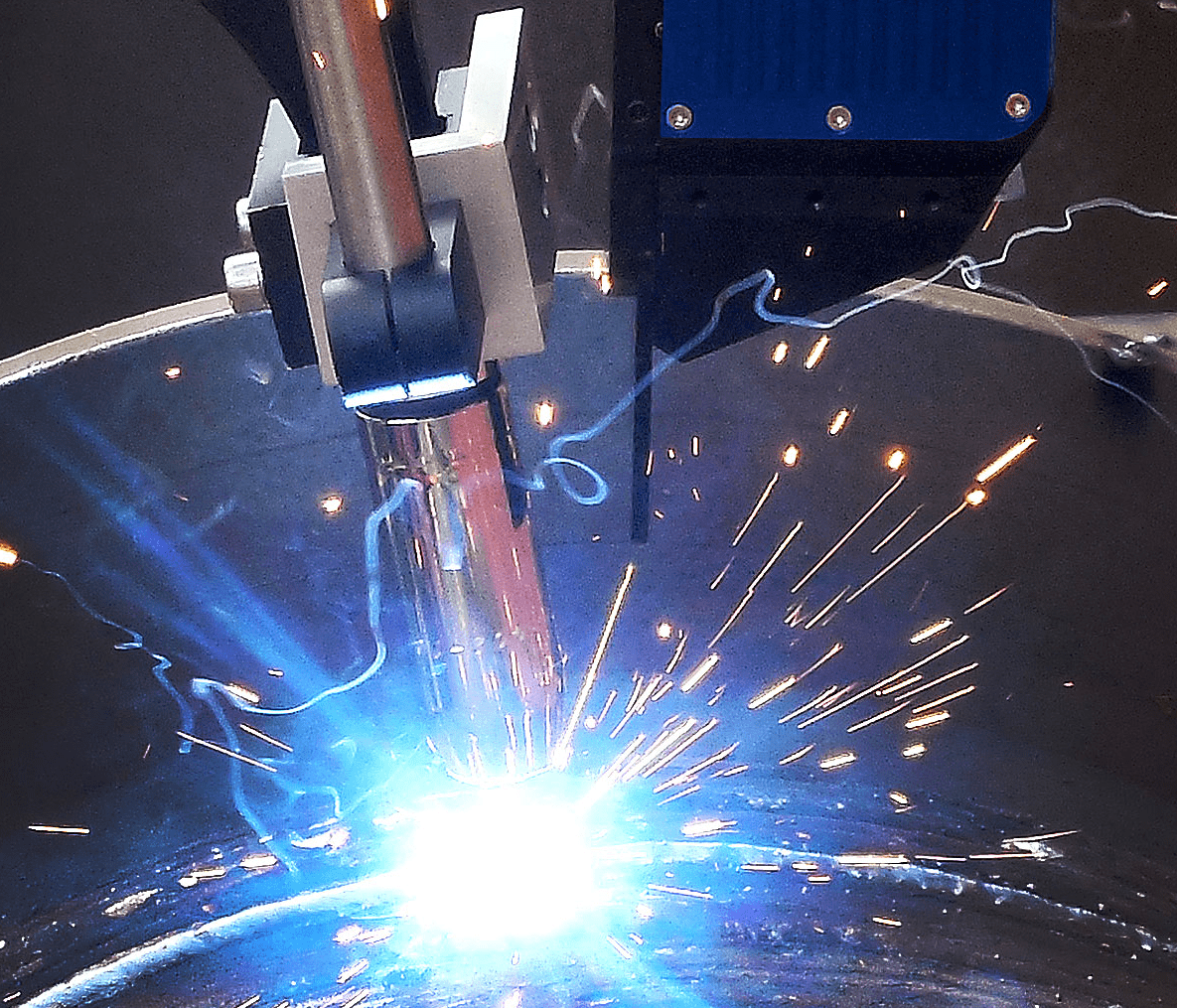

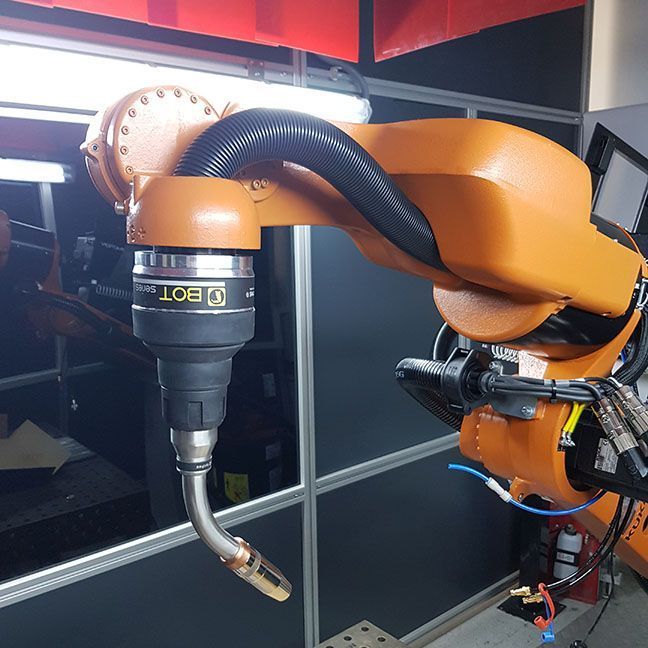

José Carlos2019-11-21T14:26:50+00:00What is your welding torch power? Learn how to choose the correct torch power. When choosing a welding torch for our equipment, one of the most important factors is the power of the gun, or what is the same, the maximum intensity of use that it can endure. Most manufacturers use the maximum intensity of use as a reference when selecting the right torch, but this reference should be understood only as that, a reference. The intensity in real circumstances will be notably lower for the following reasons. The intensity reference is always taken with 100% CO2 protection gas: this gas [...]