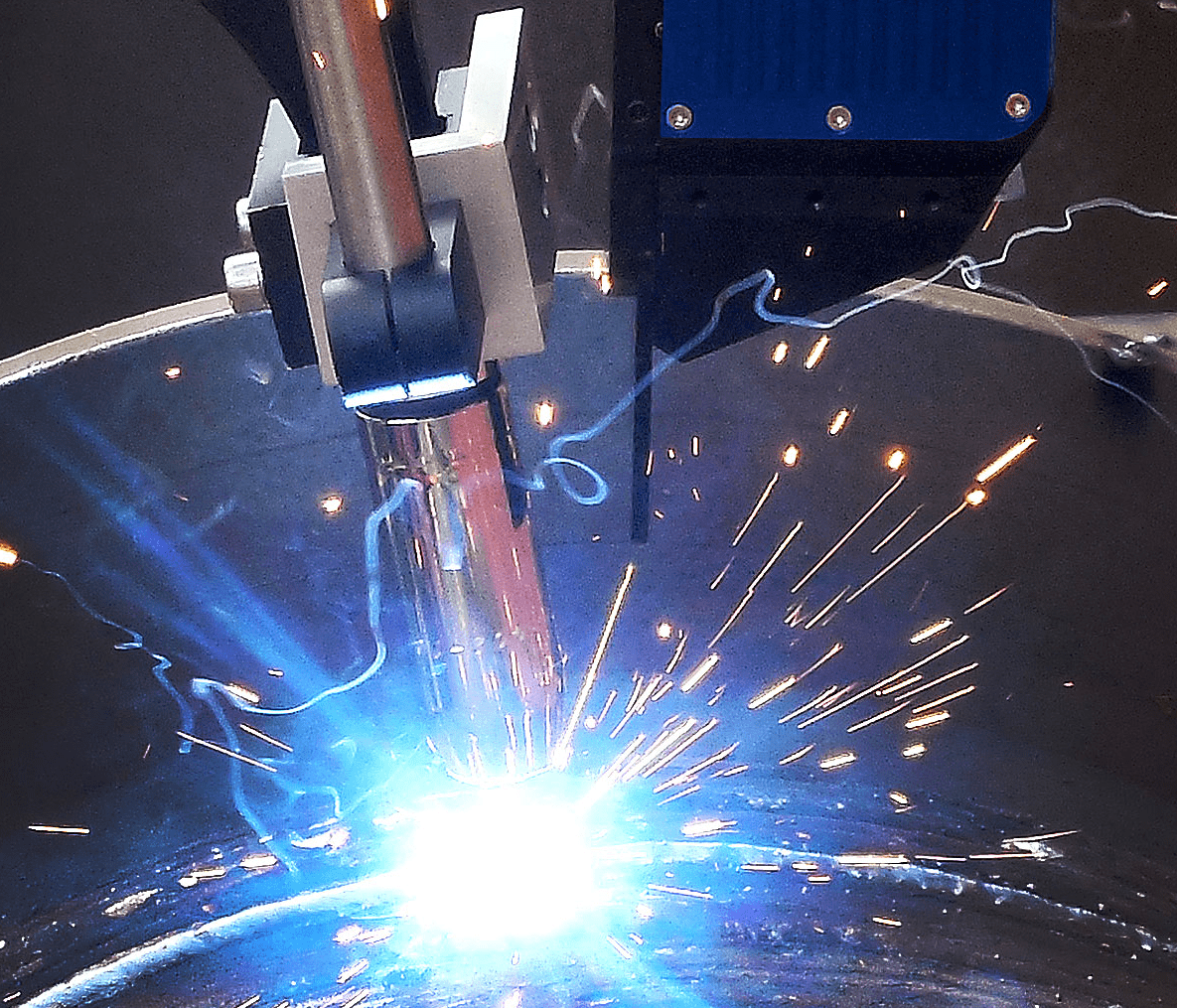

Joint tracking systems for MIG/MAG Welding Robots

José Carlos2019-04-26T06:46:44+00:00Joint tracking systems for MIG/MAG Welding Robots. Robots don’t make mistakes when welding, but we make them indeed; for instance, placing pieces and their dispersion make robots lose their welding path, causing serious problems. Currently, when we opt for a robotic welding cell in the hope of both to multiply by 3 production rates and reduce costs, we don’t tend to take into account that robots do not detect our errors: fixture design mistakes, arranging mistakes, dispersion of manufactured pieces and human mistakes when piece-feeding the robot. This translates into frustration for the production responsible when trying to meet with expected [...]