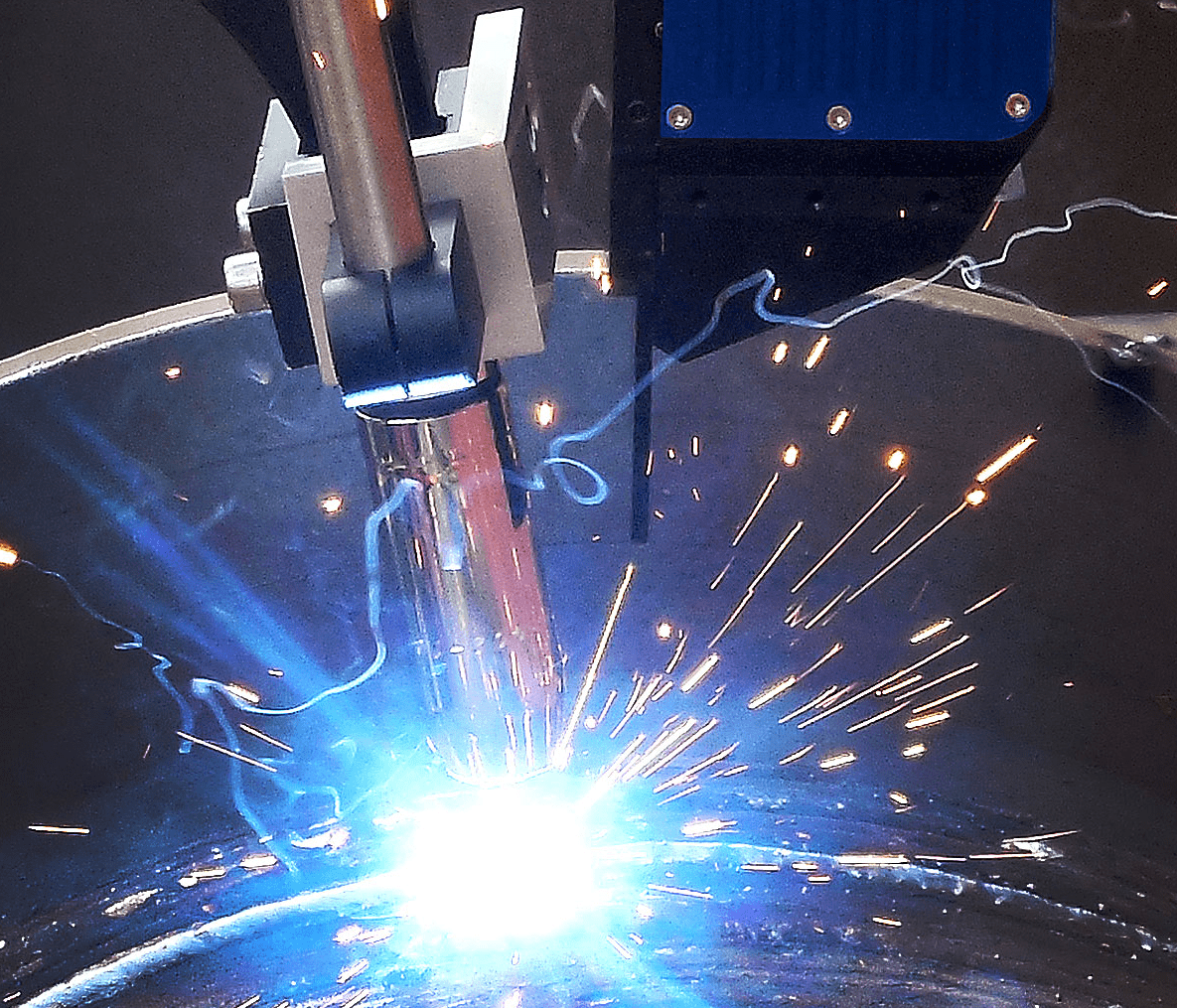

CLEANING STATIONS for welding robotics

José Carlos2020-01-22T11:10:35+00:00CLEANING STATIONS for welding robotics When a company considers to automate a welding application it is a necessity to include and think in a cleaning station for the correct maintenance and working of the complete cell. It automates three important applications: wire cutting to restart welding with the perfect wire distance to piece. nozzle cleaning of spatter stuck during the welding process through a reamering system antispatter spraying of the nozzle to avoid spattering stickness during the welding cycle The cleaning station reduces spare parts changing as it increases their durability. It also avoids welding failures in pieces and the horrible [...]